The pneumatic conveying systems allow to convey the product in powder or granules from the point of arrival (bags, big bags, hoppers and sylos) to the point of use (dosing, mixing, packaging, etc.) systems quickly, without waste or spreading. of product in the environment and automatically and safely.

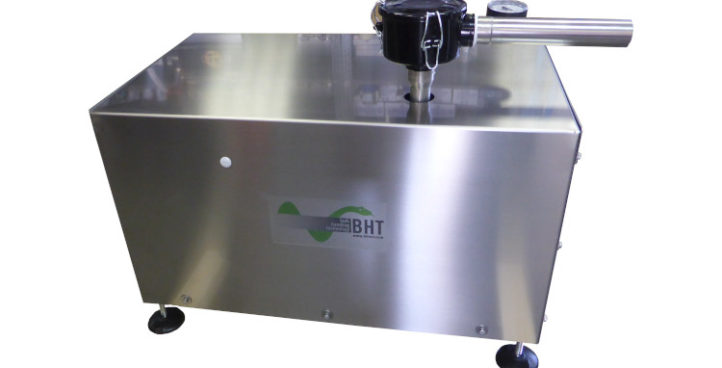

The pneumatic loaders are composed of a stainless steel tank that receives the product from the pneumatic line, a filter that intercepts excess dust and granules and an automatic outlet valve that opens when the tank is full.

They are also suitable for fragile products in place of mechanical conveying systems that tend to crush or compact the product.

Automatic dosing of a powder or granule product brings advantages in terms of dosing precision and optimization of productivity.